Introduction

In my previous post, I described Why We Cool Milk and the benefits of Milk Cooling.

Many of them who read that, asked me the next oblivious question “How”

Understanding “Why” is not going to help us the purpose of understanding, unless we know “How” to do it.

This tends me to write this post How We Cool Milk??

Let me explain what is cooling, simply the process of bringing down the temperature of any element below the surrounding temperature is cooling.

The process involved in the transfer of heat energy from one source to another.

Cooling is the removal of heat, removal of heat from milk and bringing it to a safe temperature is cooling of milk.

In today’s advanced age of technology equipment and systems are alible to the milk processor to bring down the temperature of the milk to the desired temperature by adopting suitable equipment.

Can we imagine those days when even a fridge was not available and how people keep their milk safe?

Of course, in those days milk was not supposed to keep for more than a day together as we are doing nowadays. Still, people were using some traditional methods such as keeping milk cans in flowing water, keeping cans covered with a cotton cloth, and sprinkling water over them to ensure that it remains wet, people keep milk in the earthen pot and covered with a wet cloth and hang it a height so that it comes across the flowing air to keep the pot at a lower temperature than the atmosphere.

For a long time, before the fridge, an old Russian practice was to drop a frog into a bucket of milk to keep the milk from spoiling. The researchers have shown that there could be some benefit to doing this, but you will have to drink milk in which a frog was there¹.

When the refrigeration system was developed, people started manufacturing Ice and then start using Ice Packs to keep the milk at a much lower temperature.

We are now going to discuss various milk cooling systems available at present to bring down the temperature to below 4.0 deg C so that milk can be stored at that temperature safely without spoilage.

The following three systems are nowadays widely used for milk cooling.

01. Can Cooler

02. Bulk Milk Cooler

03. Instant Milk Chilling Unit

01. Can Cooler

The basic idea of a Can Cooler is to enable chill milk in the same can where it is collected with minimum infrastructure and less capital investment. In this system effort are taken to ensure ease of operation, and less power requirement as it can be operated with the connection between 1.0 – 1.5 Kw connected load, the cleaning of the milk cans are to be done at the chilling center/dairy plant where it can be cleaned properly as manpower, as well as necessary in fracture such as hot water/steam, detergents, acid, disinfectant, etc are available. Given below are a few types of Can is coolers available for use.

The most ancient type of can cooler was like an immersion heater type where instead of a heating element refrigerant expands and thus absorbs heat from milk. A small agitator inside the can mixes milk thoroughly thus enabling equal temperature throughout the surface.

The shape of the immersion rod and agitator makes it difficult to clean properly and utmost care is required during handling as it is connected to the refrigeration line and power supply too, which makes it difficult for wide adoption. Subsequently, chilled water is being circulated instead of refrigerant still the issue with cleaning became an obstacle for it to become more popular. Given below is the type of Milk Can Water Cooler produced & marketed by Cottage Craft Works.

Recent development has brought another two models of Can Coolers which are now found getting popular. Can Coolers models, which are now

One in which a set of copper coils is used to build ice and keep the water temperature to the desired temperature which enables to bring down the temperature of the milk can submerge inside this water bath to the desired temperature.

The condensing unit is an integral part of this can cooler which is connected to the Copper Coil evaporator inside the PVC-insulated water bath. Once the Cans are submerged inside the bath, an insulated cover is kept the system close and prevents the loss of refrigeration effect. It is manufactured & marketed by The Serap Group, a company with its corporate office in France and one of its manufacturing units in India.

The latest addition to this family is from Promethean Power System, a USA-based company with its manufacturing base in Pune. The Milk Cans are kept inside the insulated box over which chilled water is glided along the outer surface thus extracting heat from milk inside the can. The system runs on their famous patented thermal storage technologies which eliminate the need for a Diesel Generator.

It needs 4 -5 hours of grid power between two milkings which produce the required cooling energy and store it in their Thermal Storage System which is utilized for milk chilling as and when required in the absence of grid power too.

The insulated box in which the cans are kept after chilling ensures minimal loss of temperature and also the smart control panel keeps on rechilling ON in a cyclic manner to ensure milk temperature does not go beyond its upper set point. These can coolers are suitable to integrate with a solar system to enable them to operate in remote villages where the availability of power is difficult.

02. Bulk Milk Cooler

The most popular and well-adopted milk cooling system is used across almost all dairies in India, popularly known as BMC. There are numbers of manufacturer Indian as well as Multinational companies that are doing a good volume of business in this sector. Installing a BMC in Village Level Milk Collection Center (VLCC) is mostly preferred by many dairies.

The BMC consists of a SS Milk Tank connected with a suitable-size condensing unit which produces the required cooling effect to abstract heat from the milk. The SS Tank is also used to store the milk till lifted by the dairy. Based on the construction of the type of cooling there are two types of BMC available,

a. DX Type

b. IBT Type

In DX or Direct Expansion type BMC, the bottom of the SS tank works as the evaporator where the refrigerant expands and gains heat from the milk. A well-designed Agitator blade with drive motors agitates the milk smoothly ensures equal temperature and also keeps the Fat content intact.

In IBT or Ice Bank type BMC, the milk storage tank is a separate tank partly submerged inside the Ice Bank where water is set on the copper coil connected to the condensing unit builds ice, and chilled the water, this chilled water is sprayed at the outer surface of the milk tank and continuous agitation inside the milk tank cools the milk.

Availability of power during milk chilling is essential in both types, so installation of an appropriate power backup system is essential, normally dairy uses Diesel Generator Set as an alternate power source during grid power failure. The BMC is available starting from 250 Ltr to 10000 Ltrs capacities.

The innovative Bulk Milk Cooler works on a PCM-based Thermal Storage system developed by Promethean Power System and has now become popular as it enables to production and storage of required cold energy when grid power is available and chill milk using the same energy in the absence of Grid power. This enables milk chilling more convenient in most erratic power conditions without using expensive Diesel Generators.

DeLaval, IDMC, ISF Industries, and The Serap Group are a few reputed and well-established manufacturers of Bulk Milk Cooler in India.

03. IMCU

Instant Milk Chilling Unit or widely known as IMCU is a system that chills milk instantly from ambient to below 4 deg C at the desired flow rate. These are suitable and economically viable for bigger size milk collection centers or milk chilling centers MCC for instant cooling of milk as these centers handle milk from 10000 LPD to 50000 LPD.

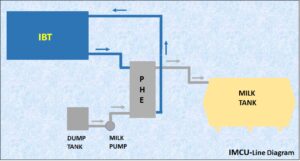

This milk cooling system consists of a large Ice Bank Tank where a lot of Ice is being produced around the refrigeration pipe which is submerged in water. The refrigeration systems have compressors and water-cooled condensers, work on the vapor absorption refrigeration cycle, and use Ammonia as a refrigerant in most cases.

A suitable capacity plate heat exchanger (PHE) used for heat transfer between the cold water from IBT and fresh milk from a dump tank thus brings down the temperature of the milk to desired temperature and this chilled milk is then stored in an Insulated Milk Storage Tank for further transportation in a Road Milk Tanker to central Dairy.

Conclusion

Irrespective of the cooling method, cooling system, and technologies used to cool milk, dairy industries always thrive for a better and quicker way of cooling milk. All of the systems have some advantages and disadvantages in terms of adoption, safety, capital investment, and so on.

Based on the requirement and suitability dairy industries are using one of these systems or a combination of all these systems to optimize the operational issues, cost, and to get better quality of milk. There is always a scope for further development of systems and equipment for the cooling of milking to discuss various milk cooling systems available at present to bring down the temperature to below 4.0 deg C so that milk can be stored at that temperature safely without spoilage.

Note: The writer of this blog is the author of the book “OMC of BMC“, a book on Operation, Maintenance and Cleaning of Bulk Milk Cooler, The book is now aviable in all major platforms.

Useful insights

Very useful key points how we cool milk olden days and now a days by useing different types of systems to safe below temp of milk. Good to learn for freshers useful and carrier of BMC.

A person essentially lend a hand to make critically articles I’d state. This is the very first time I frequented your web page and to this point? I amazed with the research you made to make this particular post extraordinary. Excellent job!

I do consider all the concepts you have offered on your post. They are very convincing and can certainly work. Still, the posts are too brief for newbies. May just you please lengthen them a little from subsequent time? Thanks for the post.

Noted

Please let me know if you’re looking for a writer for your weblog. You have some really great articles and I believe I would be a good asset. If you ever want to take some of the load off, I’d absolutely love to write some material for your blog in exchange for a link back to mine. Please shoot me an email if interested. Cheers!

I wrote a mail you regarding above but the mail got bounced, mail me on trainerprakash.com@gmail.com so that we can proceed further.

Thanks

As a Newbie, I am continuously searching online for articles that can help me. Thank you

Excellent blog! Do you have any recommendations for aspiring writers? I’m hoping to start my own website soon but I’m a little lost on everything. Would you suggest starting with a free platform like WordPress or go for a paid option? There are so many choices out there that I’m completely overwhelmed .. Any ideas? Many thanks!

Hygiene

Wow that was odd. I just wrote an very long comment but after I clicked submit my comment didn’t appear. Grrrr… well I’m not writing all that over again. Anyway, just wanted to say great blog!

An attention-grabbing discussion is worth comment. I feel that you must write more on this subject, it won’t be a taboo subject but typically persons are not sufficient to talk on such topics. To the next. Cheers

Nice post. I used to be checking continuously this blog and I am impressed! Very helpful info specially the remaining section 🙂 I take care of such info a lot. I used to be looking for this certain information for a very long time. Thank you and good luck.

Great blog here! Also your web site loads up fast! What host are you using? Can I get your affiliate link to your host? I wish my site loaded up as fast as yours lol

This is the perfect blog for anybody who wants to find out about this topic. You know a whole lot its almost hard to argue with you (not that I actually would want toÖHaHa). You certainly put a fresh spin on a topic thats been written about for a long time. Excellent stuff, just wonderful!

Thanks for the marvelous posting! I actually enjoyed reading it, you might be a great author.

I will remember to bookmark your blog and will often come back later

on. I want to encourage continue your great posts, have a nice morning!

Also visit my web blog; automatenspiele Der 80er

Hi…

Thanks

Wow, incredible blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of your web site is wonderful, let

alone the content!

Also visit my web-site: Die-Rheinischen-bauern

Hi..

Thanks for your comments.

I’m amazed, I have to admit. Seldom do I encounter a blog

that’s both equally educative and interesting, and without a

doubt, you’ve hit the nail on the head. The problem is an issue

that too few men and women are speaking intelligently about.

Now i’m very happy I came across this in my hunt for something concerning this.

my webpage … Bestautoservice

Hi…

Thanks for your amazing feedback, it’s my pleasure.

What a information of un-ambiguity and preserveness of precious familiarity on the topic of unpredicted emotions.

Feel free to surf to my blog :: gratis geld bij online casino [Russell]

What’s up, all the time i used to check weblog posts here

early in the dawn, for the reason that i like to gain knowledge of more and more.

my web site; gratis echte gokkasten spelen (Trudi)

Hello, I enjoy reading through your post. I like to write

a little comment to support you.

Also visit my blog post – kansspelbelasting in casino (Roxanna)

Good post. I learn something totally new and challenging on websites I stumbleupon on a daily basis. It will always be useful to read content from other authors and use something from their websites.

I was just looking for this info for some time. After six hours of continuous Googleing, finally I got it in your website. I wonder what is the lack of Google strategy that do not rank this type of informative websites in top of the list. Generally the top web sites are full of garbage.

Pingback: Basics Of Milk Cooling Technology You Need to Know 🧊

Thank you Prakash ji for this insightful blog. It actually throws light on how traditionally milk used to be cooled, without a refrigerator. But with the help of technology these days, this problem is not a problem anymore. For example, Prompt MilkoChill. I am aware that we have discussed this before, but with the help of our genius kids at IIT Bombay, we were able to develop a machine which works under erratic power supply, and also with the help of solar energy. Please go through the product, as I believe this is a revolution, that holds the capability of improving the quality of milk at source, also helping millions across the villages in India. This is the link https://www.promptdairytech.com/milkochill-instant-milk-chiller

Thanks Devika for your time to go through my blog and your comment. I have seen the product displayed during IDA exhibitions. Really it a good product to address the issue pertaining to the small farmers. The CIP system is really an added advantage to ensure proper cleaning thus maintaining hygiene which is essential. Thanks once again and would love to hear any further development of such products by PROMPT.