Introduction: What is Small-Scale Milk Processing?

Milk is one of the most consumed products worldwide. The data provided by FAO in 2018, the average food consumption per person is approximately 675.2 Kg per annum. Out of which milk consumption is approximately 79.3 Kg per person which is about 12% of all food consumed worldwide. This is followed by Rice, Wheat, Potatoes, Meat, Seafood, and so on.

Milk is the most perishable item among the food products we consume. That is the reason its processing is an important task. Apart from large commercial Milk Processing Units, a Small-scale Milk processing business plays an important role ensures a safe and healthy product for consumption in local markets.

Small-scale milk processing refers to the production and packaging of milk and milk-based products on a smaller scale. This type of processing is typically done by small farmers, co-operatives, or local businesses.

All activities starting from milk collection, storage, pasteurization, packaging, and marketing is carried out by the entrepreneur. It serves as an ideal approach for rural communities with limited resources and access to modern food-processing technologies. It also brings benefits to the local community by generating jobs in milk collection, transportation, processing, and sale. Additionally, small-scale milk processing often promotes the local economy and sustainable farming practices.

Small-scale processing allows dairy farmers to market their products at a better price, increasing their profits and helping them remain competitive in the market. It can also provide more diverse options for consumers, offering specialty products. With the right equipment and knowledge, any small farm can begin producing and selling high-quality dairy products that will delight customers.

One of the benefits of small-scale milk processing is that it allows for greater control over the quality of the final product.

The Basics of Starting & Running a Small-Scale Milk Processing Business

Starting a Small-scale Milk Processing business can be overwhelming and complicated for first-time entrepreneurs. There are many hats to wear, boxes to check, and things to do. It needs to be planned properly to have a sustainable business. It can be a profitable venture with the right tools, knowledge, and expertise.

Any business needs the “Three M”, the Man, Material & Machine, and of course Money to get all of them. These are essential elements all successful start-ups need to have in place before going into business. Let us deep dive into these elements when it comes to the Small-scale Milk processing business.

01. Material

Milk is the raw material for a Small-scale Milk processing business. You need to understand how to get milk. There are two sources that you can consider.

- Your own Cattle Farm

- Sourcing Milk from other Farmers or Milk Producer’s Group

There are advantages and disadvantages associated with the above two sources.

To have your own cattle farm, the initial investment will be high to procure land, construct buildings, purchasing cattle and ancillary items. Not only investment it also takes ample time to get the setup ready.

To procure milk from other farmers although the investment is less than own farming, it needs lots of effort to bring the farmers together by forming a milk producers’ group. Internal politics and dealing with human beings with different mentalities are other hurdles you need to overcome. You will have proper planning, a code of conduct, and by-laws in place to handle the milk producers’ group.

To have a sustainable business and uninterrupted milk supply you need to consider a combination of both sources. It will be better to start with procuring milk from the milk producers’ group and in the latter days to have your own cattle farm for redundancy in milk availability.

02. Machine

The term Machine does not mean only the types of machinery required for processing the milk. Land & Buildings and the necessary infrastructure required for milk processing will form a part of this.

To start with you need to finalize the products you need to manufacture to suit the local market. Various processes such as standardization, pasteurization, homogenization, cream separations, packaging, etc. are required to process the raw milk into a final marketable product.

Based on the product to be manufactured, the process of manufacturing, and the number of various products to be manufactured the suitable equipment is then selected. The level of automation and integration of the process line plays a major role in the selection of equipment & types of machinery. The capacity of the equipment is so selected that when required the capacity can be enhanced with minimal expenses.

Once the machinery is finalized, then it comes to the design of the building and other infrastructures. The following points must be considered while selecting the location of the processing plant.

- The proximity of Raw Milk.

- Cost of Land & Soil condition

- Roads for transportation of Raw Materials & Finished Products.

- Relatively cheap Energy (Electric Power)

- Adequate good quality Water.

- Availability of both skilled & non-skilled Manpower.

- Local Climatic Conditions for wind & dust.

- Drainage connectivity for the disposal of Wastewater.

- Proximity to Local Market for product delivery.

- Statutory Law by the Government & Local Bodies if any.

The details of equipment and machinery are described in a separate section.

03. Manpower or Human Resource

Manpower or Human Resources is of primary importance for any productivity activities. Milk processing plants are highly labor intensive. Manpower needs to be selected and deployed properly for maximum output and smooth running of the operation. Proper work culture and suitable policies & strategies should be in place for the motivation of the workers.

The entire workforce is categorized as,

Procurement Team:

The members are responsible for milk procurement and allied services such as the supply of feed & fodder, veterinary services, etc. provided to farmers. The team constantly focused on increasing the volume as well as the quality of raw milk procured. Optimizing the procurement cost by optimizing the milk collection route is taken care of by this team.

Processing Team:

The members are responsible for milk processing, and the operation of equipment & machinery. Schedule, as well as breakdown maintenance, are taken care of by the processing team. They also ensure the quality of the product going out to the market.

Marketing Team:

The members of the team oversee selling processed products and managing all marketing efforts. Their task also includes selecting dealers/distributors, securing orders, gathering market feedback, expanding the marketing network, conducting market analysis, and assessing product demand.

A small team for administration and accounts are also the part of Marketing Team and supports all three team members based on their requirements.

The owner of a small-scale milk processing business wears many hats, serving as the chief executive and taking charge of all planning and strategy. He maintains inter-departmental coordination and relationships to ensure the smooth operation of the business.

Equipment Necessary for Setting Up a Small-Scale Milk Processing Plant

Careful planning and investment in the right equipment is the key factor when it comes to starting a small-scale milk processing business. Here are some major pieces of equipment you will need to get started.

The equipment can be broadly divided into 03 sections.

- Milk Reception & Storage Section

- Processing & Packaging Section

- Utility Section

01. Milk Reception & Storage Section:

Raw fresh or chilled milk is received at the processing plant either in cans or tankers. The milk reception dock is designed at an elevated level to handle the cans. The dock should have adequate space for unloading the cans. Samples are taken from each can and tanker for testing. After the preliminary tests if milk is found in good condition, the cans or tanker is emptied to the weighing unit and then to the Dump Tank for further processing.

The standard milk reception rate is to be 100 liters per min, hence around 6000 liters of milk can be received in an hour. This helps in deciding the equipment required for further handling.

The Milk Reception & Storage Section will have the following major equipment.

- Can Tipping Bar provide support for emptying Milk Can

- Weighing Scale to weigh the milk received.

- Dump Tank to dump milk after weighing the milk.

- Milk Transfer Pump to pump milk from Dump Tank-Chiller-Storage Tank.

- Milk Chiller (PHE Type) to chill the milk to 4⁰ C instantly.

- Milk Storage Tank to store & maintain the temperature of the milk.

- Sour Milk Separator to separate cream (FAT) when required.

- The Can Scrubber to clean the cans after the milk is emptied.

- Crate Washing Tough to clean the Milk Crates that come from the market.

- Small Laboratory to conduct platform test & recording of milk received.

02. Processing & Packaging Section

Milk processing is done to preserve milk for more days and helps to reduce food-borne illnesses. Milk processing is also done to convert Raw Milk into various milk products. In the context of a small-scale milk processing plant, we will discuss only the common processes carried out for the production of Liquid Milk. The following processes are carried out in any milk processing plant.

- Standardization

- Pasteurization

- Homogenization

- Separation

Standardization:

Standardization of milk refers to the adjustment (raising or lowering) of the milk FAT and Solids Not Fat (SNF) content of milk to prepare different varieties of milk. For example, double-toned, toned, standardized milk, etc. as per the market demand.

Standardization provides consumers with the desired quality of milk and ensures consistency. It ensures economics in production. It is also essential to comply with the legal requirements for milk or milk products.

The process involves the removal of excess FAT content and the addition of Skim Milk Powder (SMP) to achieve the desired percentage based on the type of milk. The Production Manager follows either Pearson’s Square Method or Algebraic Equations to calculate the amount of FAT to be removed and SMP or Water to be added to bring the milk to desired FAT & SNF content.

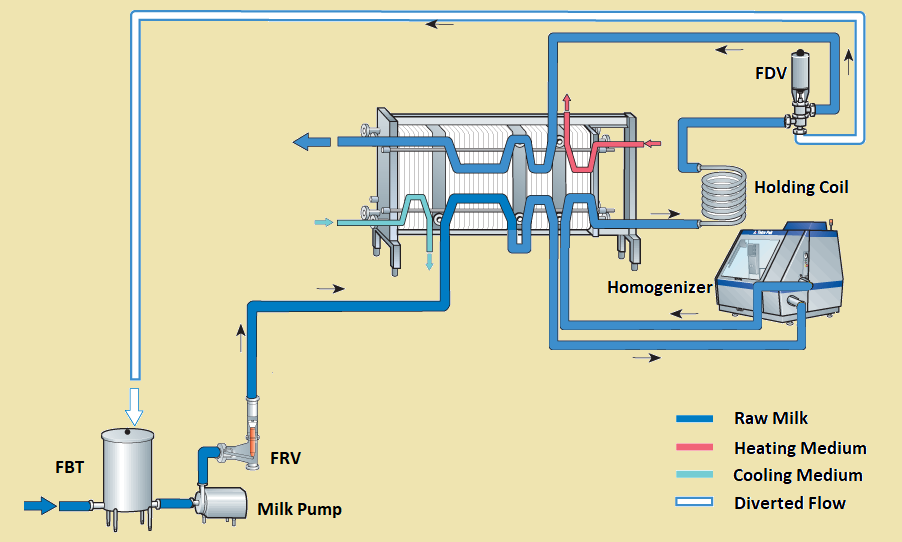

Pasteurization:

Pasteurization is the process of heating milk to a specific temperature and holding the milk at that temperature for a specific. It kills harmful bacteria that can lead to diseases like listeriosis, typhoid fever, tuberculosis, diphtheria, and brucellosis. It extends the life of the milk & milk products depending on the method of pasteurization adopted. The following Three types of pasteurization methods are used in dairy.

- LTHT – Low-Temperature Hight Time

- HTST – High-Temperature Short Time (most adopted in dairy)

- UHT – Ultra High Temperature

HTST method of pasteurization is widely used in dairy and recommended for small-scale milk processing as it is affordable and more reliable.

Homogenization:

Homogenization is the process of breaking down FAT globules into minuscules present in the milk. The advantage of this process is that breakdown the fat globules into very small sizes using high pressure. So FAT globules become more uniform, and therefore the fat will remain more evenly dispersed throughout the milk. This is important for creating a consistent product and improving the shelf life of the milk. The equipment used is called a Homogenizer. This works in line with the pasteurization process.

Separation:

Separation is a process in which Cream or FAT is separated from the Milk by the process of centrifugation. Cream being lighter in weight starts floating over Skim Milk.

The equipment used for this purpose is called a Cream Separator. A cream Separator works both in line with the pasteurizer and independently depending on the quantity of milk separation. An offline Cream Separator is commonly used in small-scale milk processing units.

Packaging:

Milk is packed in HDPE (High-Density Polyethylene) pouches using a Pouch Filling Machine. The automatic pouch-filling machines are available starting from 1000 PPH to 3000 PPH for Single Head type and up to 6000 PPH for Double Head Machines.

Some processors use Glass & Plastic bottles for packaging milk depending on their marketing strategy and convenience.

03. Utility Section

Utilities are essential services that play the most important role in a milk processing plant. The utilities required for a small-scale milk processing plant are,

Air: Pressurized Air required for most of the pneumatic controlled valves, packaging machines, etc. obtained from an Air Compressor.

Water: Essential for cleaning equipment & process lines, feeding to Steam Boiler or Hot Water Generator, and making chilled water for milk chilling. Good quality water is required for this purpose.

Refrigeration: Refrigeration is the heart of a milk processing plant and consumes the most energy. The produces cold water for Milk Chilling, maintaining the desired temperature of the cold room for product storage.

Steam or Hot Water: Steam or Hot Water is required for heating the milk during pasteurization and manufacturing different milk products such as Curd, Paneer, Ghee, etc. Hot water is also required for cleaning the equipment and process line after each batch of processing.

Effluent Treatment Plant: An Effluent Treatment Plant or ETP is essential to process the wastewater produced during milk processing. The ETP cleans wastewater and removes any organic matter, suspended solids, toxic and non-toxic materials, and chemicals. The treated water can be then reused or released into the environment which will do less harm to the environment.

Diesel Generator: Diesel Generator Set or D. G. Set of required capacity is installed in the plant for providing electric energy backup in case of main power failure to prevent interruption in milk processing.

Click Here to get a detailed equipment list for a Mini Dairy, Capacity – 5 KLPD

Legal Requirements for Starting a Small-Scale Milk Processing Business

Starting a small-scale milk processing business involves several legal requirements that must be followed to ensure compliance with industry standards and regulations.

Business Registration: It is important to register your business as a legal entity to ensure that it is recognized by the government and the public. You can register as a Sole Proprietorship, Partnership, or Limited Liability Company, depending on your preference and the size of your business.

Licenses and Permits: Obtaining the necessary licenses and permits is crucial to operating a legal and compliant milk processing business. You will need a food processing license, a dairy plant permit, and a business operating license.

FSSAI Licensing: The Food Safety and Standards Authority of India (FSSAI) is responsible for regulating the food industry in India. You will need to obtain an FSSAI license to operate your milk processing business.

Health and Safety Regulations: The food industry is heavily regulated, and your milk processing business must comply with all health and safety standards. This includes adhering to Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), Pollution Controls Clearance, and ensuring that your facilities meet sanitation requirements.

Insurance: It is recommended to purchase liability insurance to protect your business against any potential legal claims. This will cover you in case of any accidents or illnesses caused by your products.

Product Labeling and Packaging: The labeling and packaging of your products must meet regulatory requirements and accurately reflect the content and weight of your products.

Taxation: You must ensure that you are paying the correct amount of taxes to the government. This includes obtaining a tax identification number and registering for Good & Service Tax (GST).

By following these legal requirements, you can ensure that your small-scale milk processing business operates in a compliant and sustainable manner. It is advisable to consult a lawyer or an industry expert for more specific requirements depending on the place of business.

Marketing Strategies for Your Small-Scale Dairy Products

Marketing your small-scale dairy products in India is a crucial step to reaching customers and building your brand. Here are some marketing strategies that can help you reach your target audience and grow your business.

Social Media Marketing: Utilize social media platforms like Facebook, Instagram, and Twitter to reach a large audience and showcase your dairy products. You can post pictures, videos, and descriptions of your products, and also use social media to run promotions and contests.

Networking: Attend trade shows and exhibitions to meet potential customers and other industry professionals. This can help you build relationships and increase brand awareness.

Local Advertising: Advertise your dairy products in local newspapers, magazines, and radio stations. This will help you reach your target audience and create brand recognition in your community.

Sampling Programs: Offer samples of your dairy products to customers to try and provide them with an opportunity to taste your products. This will help you build brand loyalty and increase sales.

Partnerships: Partner with local grocery stores, supermarkets, and restaurants to sell your dairy products. This will give you a wider reach and increase brand visibility.

Customer Feedback: Encourage customers to provide feedback and suggestions about your products. Use this feedback to improve your products and services, and also to showcase customer satisfaction on your website and social media channels.

Online Presence: Build a website and an online store to reach customers and sell your dairy products. You can also offer online promotions and discounts to attract customers.

By implementing these marketing strategies, you can increase brand awareness and reach a larger audience, leading to increased sales and growth for your small-scale dairy business in India.

Conclusion:

Starting and running a profitable small-scale milk processing business requires careful planning and attention. Following best practices in operations, marketing, and financial management, you can ensure the success and profitability of your business. Some of the tips I personally experienced while working with such startups are shared below.

Focus on Quality: Production of high-quality products alone will be not beneficial. It is essential to maintain consistency in quality to build trust among consumers and to attract new consumers.

Streamline Operations: Implement efficient systems and processes to reduce costs and improve productivity. Remember human fails but the system works.

Diversify Your Product Line: Bringing a new variety of products attracts a wide range of customer & increase sales. This will help you stay ahead of the competition.

Utilize Effective Marketing Strategies: Use social media, local advertising, and other marketing strategies to reach your target audience and build your brand.

Manage Finances Carefully: Proper financial management is crucial to the success of any business. Keep accurate records, control costs, and invest in your business to ensure long-term profitability.

By following these best practices, you can make your small-scale milk processing business profitable and sustainable. With hard work, dedication, and a commitment to quality, you can turn your dream of starting a successful dairy business into a reality. Remember Small-scale Milk Processing Business is profitable, but it needs personal involvement and patients in the initial days until you reach break even.