Introduction

We all know that milk needs to be stored at a lower temperature. Hence Milk Cooling is essential.

Although it is not required for UHT milk which is popularly known as Tetrapack Milk.

That is the reason when we got the milk at our doorstep, we boiled it immediately or keep it inside the fridge.

Even after boiling also, we keep the milk inside the fridge.

In older days people store milk in an earthen pot (matka) and hang it at a suitable place to ensure that milk kept at a lower temperature than the ambient and in many cases, they store it overnight.

Of course, hanging at a height it protects the milk from domestic animals like dog/cat and also from children.

The very first reason to keep milk at a lower temperature is to keep it fresh and safe from spoilage.

Milk has a self-life of approximately 04 hours when it comes out of the animal Udder, so it needs to be chilled to a specified safe temperature as soon as possible and this temperature is to be maintained during the entire chain starting from milk collection centers to end consumer.

This is the biggest challenge for all who are engaged in the milk & milk product business. Demand for a better quality of milk to produce milk products with a longer self-life added more to it.

So, it became necessary to cool milk at the source, I mean at the farm or at least at the center where milk is collected and further transported to dairy plants.

Benefits of Milk Cooling

Apart from keeping milk fresh, there are more benefits which of interest to milk processors to cool the milk.

- To inhibit bacterial spoilage.

- To extend the storage on the farm/collection centers

- To minimize milk transport costs

- To improve raw milk quality delivered

- Increase profit for farmers and dairy industries

01. To Inhibit Bacteria Spoilage

We all know that milk contains Fats, Proteins, Carbohydrates, Vitamins, Minerals, and Amino acids that provide an ideal environment for the growth of many microorganisms.

The Lactic Acid Bacteria (LAB), which ferment lactose to lactate is present in milk. The most common LAB milk are Lactococcus, Lactobacillus, Leuconostoc, Streptococcus, and Enterococcus.

These bacteria called Lactobacillus to grow exponentially when milk kept at room temperature and lactose transforms to Lactic Acid. This causes lowering the pH value of the milk so milk tests sour. The structure of proteins such as casein will change causing milk to curdle and forms clumps. This results in a change in taste, change in smell, and thickness of the milk.

In order to prevent the growth of bacteria, milk must be chilled to < 4 Deg C within 04 hours of milking and it is then stored at that temperature till brought to the processing plant for further processing. The cold chain is maintained to safeguard the milk till it is processed further such as pasteurization or product.

02.To Extend the Storage on the Farm

The milk collected at collection centers and farm are picked up by dairy plant for further processing, but it is practically not possible for the milk processor to lift the milk immediately from all collection center as well as farms as it will take time for milk collection and transportation. So it became necessary to store the milk at the source until it is being lifted and transported o the milk processing plant. As we discussed earlier milk will spoil if stored at room temperature then it is necessary to chill milk below 4 Deg C and stored at that temperature to prevent the growth of bacteria and thus prevents spoilage of milk.

03.To Minimize Transportation Cost.

Cow gives milk twice a day, so milk is collected twice a day and needs to be brought to the processing plant twice a day if not chilled and stored properly.

Thus, it is suggested to spend on infrastructure to chill and store milk at the collection centers and farms and lift it once a day as convenient for the processing plant. This reduces the transportation cost to the processor.

Further, since milk is to be stored at the collection center, and there is no hurry and fear of missing the truck departure time, farmers are allowed a larger window to pour their milk at the center. This results in more farmer association and hence a rise in milk volume is also observed.

04.To Improve Raw Milk Quality delivered

Chilling of milk restricts the growth of bacteria so retains the original quality of milk in terms of the number of bacteria. When a proper cold chain is maintained from sources of milk collection to the dairy reception dock it ensures getting a better quality of raw milk in comparison to a system when milk is collected and transported to the dairy plant at ambient temperature.

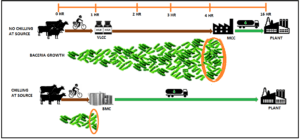

An illustration is given below showing the difference between milk collection with and without chilling facilities at VLCC (Village Level Collection Center)

05. Increase Profit for Farmers and Dairy Industries

Chilling Milk at the source restricts the growth of bacteria and minimizes the chances of spoilage of milk thus it benefits both farmers as well as dairy plants. Normally milk processor does not pay the cost of the milk which has been spoiled or about to spoil at the time it reaches the dairy dock. Even though dairy does not pay the cost still dairy loses the amount he spends towards other activities he does for the collection of milk such as transportation, labor, etc.

Eliminating spoilage benefits both farmers and milk processors, it also builds trust among themselves. Farmer became more confident in the return on investment he is encouraged to invest more in purchasing cows for better earning.

To have good milk quality means satisfied customers and satisfied farmers. That is the reason milk processors keep on building infrastructure such as Chilling Centers, Bulk Milk Coolers, Can Chillers and looking for all possible alternatives to suit their requirement so that milk can be chilled at the source or at least very nearer to the source to enable them to get better quality and assured quantity of milk round the year. Although as of now still the facility and infrastructure developed are not adequate to cater to the need still milk processors with keep on investing in infrastructure and also Govt of India through its nodal agency NDDB is launching various schemes and project to strengthen the cold chain in the milk business.

Some statics and figures are there in the video attached herewith.

Really helpful information to understand the dairy science aspect of BMC’s. Also beneficial for us to increase our skill set in understanding dairy technology along with our respective working domain.

Excellent blog here! Also your site loads up fast! What host are you using? Can I get your affiliate link to your host? I wish my website loaded up as fast as yours lol

This is the perfect blog for anybody who wants to find out about this topic. You know a whole lot its almost hard to argue with you (not that I actually would want toÖHaHa). You certainly put a fresh spin on a topic thats been written about for a long time. Excellent stuff, just wonderful!

Good post. I learn something totally new and challenging on websites I stumbleupon on a daily basis. It will always be useful to read content from other authors and use something from their websites.

Hi. Prompt Dairy Tech has come up with an instant milk chilling solution, it is called Prompt MilkoChill. I think this will be a great product for the farmers to chill milk instantly, and it also comes cheap. We can know more about this at https://www.promptdairytech.com/milkochill-instant-milk-chiller

Thanks Devika, I had published a blog “How we Cool Milk”, where I have given some details of other two can chillers available in the market, unfortunately I had not much details about this product so I left it. However will try to incorporate in my future blog.

Thank you so much Prakash ji.